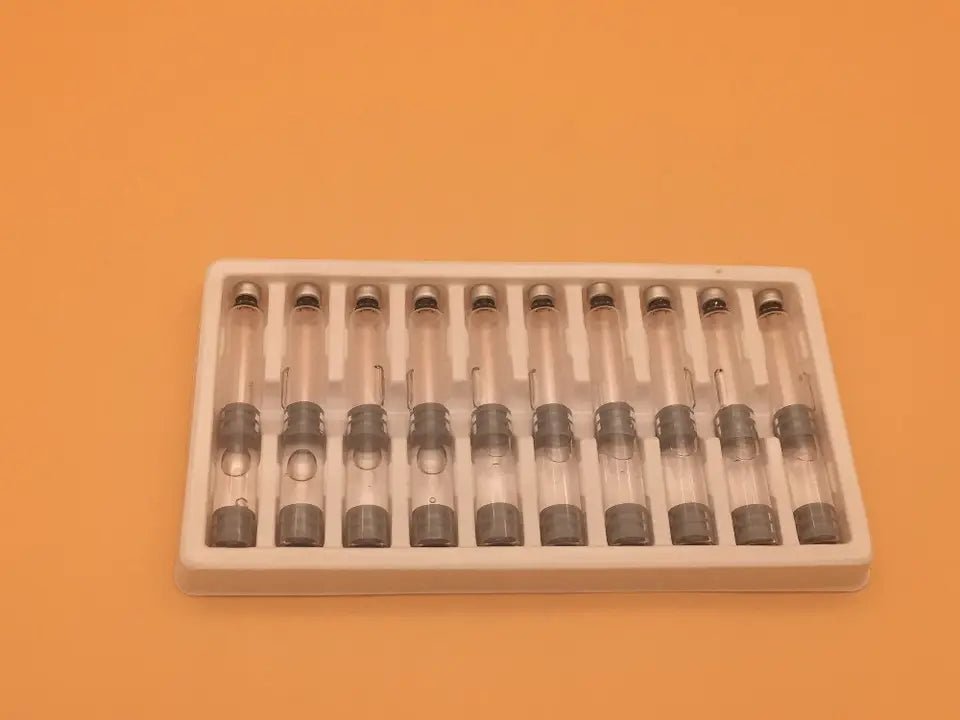

Superior Storage and Stability

Nuestro Dual Chamber Cartridges ensure optimal storage and stability for your medications. Featuring an advanced dual-chamber system, these cartridges allow for separate storage of substances until the point of use, maintaining the efficacy and shelf life of sensitive ingredients. Whether you’re using a Pen Cartridge or an Insulin Cartridge, the design ensures maximum performance and reliability.

Versatile Application

These Dual Chamber Cartridges are ideal for a variety of applications, including double chamber vials and Cartridges Double Chamber for insulin delivery. They support a wide range of medications and are compatible with multiple pen systems, making them perfect for patients and healthcare providers seeking versatile and dependable solutions.

Enhanced User Experience

Experience ease and convenience with our dual-chamber system. Designed to simplify the mixing process, these cartridges reduce preparation time and ensure accurate dosing. Perfect for both home and clinical settings, they enhance the overall user experience, especially when used as Pen Cartridges or Cartuchos de insulina.

High-Quality Construction

Manufactured with premium materials, our Dual Chamber Cartridges are built for durability and reliability. Each double chamber vial is crafted to meet stringent quality standards, ensuring that every dual chamber vial provides consistent and safe performance. Trust in our high-quality Cartridges Double Chamber for your medical needs.

Cost-Effective Solutions

Nuestro Dual Chamber Cartridges offer a cost-effective solution for medication delivery. By enabling precise mixing and dosing, they minimize waste and ensure that each dose is administered accurately. This efficiency not only improves patient outcomes but also offers significant cost savings over time, making our dual-chamber system a smart investment for healthcare providers.

Dual Chamber Cartridges

Dual chamber cartridges represent a significant innovation in the field of dispensing technology. Unlike single chamber systems, which hold a single component, dual chamber cartridges are designed to store and dispense two separate components simultaneously. This feature is particularly beneficial for applications requiring precise mixing of materials just before use, ensuring optimal performance and consistency.

The primary purpose of dual chamber technology is to facilitate the efficient and accurate mixing of two-part systems, such as those found in various adhesives, sealants, and pharmaceutical formulations. These cartridges are engineered to maintain the individual integrity of each component until the point of application, thereby preventing premature reactions and degradation. This controlled mixing process is essential in achieving the desired chemical properties and ensuring the effectiveness of the end product.

One of the most common applications of dual chamber cartridges is in the pharmaceutical industry. Here, they are used to store and deliver complex medications that require precise dosing and mixing at the time of administration. This technology ensures that the active ingredients remain stable and effective until they are ready to be used by the patient.

In the realm of adhesives and sealants, dual chamber cartridges are indispensable in industries such as construction, automotive, and electronics. These cartridges allow for the efficient dispensing of reactive components that, when combined, form strong, durable bonds. The ability to accurately mix and apply these substances is crucial in maintaining the structural integrity and functionality of various products and infrastructures.

Overall, dual chamber cartridges offer a versatile and reliable solution for a wide range of applications that demand precise mixing and dispensing of two-part systems. Their unique design and functionality make them an essential tool in industries where accuracy, efficiency, and consistency are paramount.

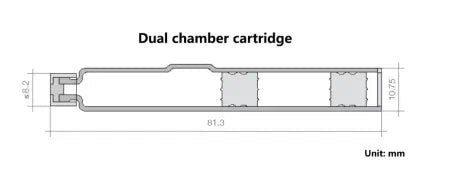

Structure and Design of Dual Chamber Cartridges

Dual chamber cartridges are meticulously engineered to provide precision and efficiency in various applications. At their core, these cartridges consist of two distinct chambers, each designated for housing different substances. This bifurcated design is fundamental to their functionality, enabling the simultaneous but separate storage of materials that may react or degrade if mixed prematurely.

The primary structure of dual chamber cartridges comprises an outer shell typically made from robust materials such as high-density polyethylene (HDPE) or polypropylene (PP). These materials are chosen for their excellent chemical resistance and structural integrity, ensuring that the contents are well-protected from external contaminants and physical damage. Inside this outer shell, the two chambers are often delineated by a central barrier or a collapsible membrane, which maintains the separation of contents until the point of use.

One of the critical design elements of dual chamber cartridges is the mechanism that facilitates the mixing of contents. This can be achieved through various methods, such as a breakable seal or a plunger system. For instance, in some designs, a movable piston within the cartridge can be activated to break the central barrier, allowing the contents of both chambers to mix. Alternatively, a dual syringe setup may employ a plunger that, when depressed, simultaneously expels the contents from both chambers through a common nozzle, ensuring thorough mixing.

Moreover, specific dual chamber cartridges are designed with precision dosing features. These might include graduated markings or adjustable dispensing mechanisms that allow users to control the exact amount of material mixed and dispensed. Such features are particularly beneficial in medical and industrial applications where precise measurements are crucial.

The structural and design elements of dual chamber cartridges are integral to their function, providing a reliable solution for the separate storage and controlled mixing of various substances. This meticulous engineering ensures that the contents remain stable until they are ready to be used, enhancing the efficiency and safety of the application process.

Advantages of Using Dual Chamber Cartridges

Dual chamber cartridges offer a significant advancement over traditional single chamber systems, providing a range of benefits that enhance both the application process and the final product’s quality. One of the primary advantages is improved storage stability. By separating the components until the moment of use, dual chamber cartridges prevent premature reactions, thereby extending the shelf life of the materials. This is particularly valuable in industries where materials are costly or sensitive to environmental conditions.

Another key benefit is the precise mixing ratios that dual chamber cartridges facilitate. Traditional single chamber systems often rely on manual mixing, which can lead to inconsistencies and compromise the final product. Dual chamber systems, however, ensure that the components are mixed in exact proportions every time, resulting in a more reliable and high-quality output. This precision is crucial in applications such as medical adhesives and industrial sealants, where even slight deviations can significantly impact performance.

Reduced waste is another significant advantage of dual chamber cartridges. With single chamber systems, leftover material often hardens and becomes unusable, leading to unnecessary waste. Dual chamber cartridges mitigate this issue by allowing users to dispense only the amount needed, keeping the remaining material fresh for future use. This not only cuts costs but also supports environmental sustainability by reducing the amount of discarded material.

Enhanced user safety is a further benefit of dual chamber cartridges. By automating the mixing process, these systems minimize the risk of exposure to potentially hazardous chemicals. In industries such as healthcare and construction, where safety is paramount, this feature is invaluable. For instance, in dental applications, dual chamber cartridges enable the safe and accurate mixing of dental cements, reducing the risk of incorrect formulations that could harm patients.

Real-world examples underscore the effectiveness of dual chamber cartridges. In the automotive industry, for example, manufacturers have reported enhanced bond strength and durability in vehicle assembly lines when using dual chamber systems. Similarly, in the electronics sector, precise mixing has led to improved performance of thermal interface materials, crucial for the longevity and reliability of electronic devices.

Overall, the advantages of dual chamber cartridges—improved storage stability, precise mixing ratios, reduced waste, and enhanced user safety—make them a superior choice for a wide range of applications, leading to better outcomes and greater efficiency.

Applications in the Pharmaceutical Industry

Dual chamber cartridges have revolutionized the pharmaceutical industry by offering an innovative solution for storing and administering complex medications, including biologics and vaccines. These cartridges are designed to keep two components separate until the moment of administration, ensuring the stability and efficacy of the medication. This is particularly beneficial for biologics, which often require precise handling and storage conditions to maintain their therapeutic properties.

One of the primary applications of dual chamber cartridges is in the administration of vaccines. Many vaccines consist of a lyophilized (freeze-dried) component and a liquid diluent. Dual chamber cartridges allow these components to be stored separately, which is essential for maintaining the vaccine’s potency. When ready for use, the two chambers are mixed within the cartridge, providing a fresh and effective dose. This method not only enhances the safety and efficacy of vaccines but also simplifies the administration process for healthcare professionals.

In addition to vaccines, dual chamber cartridges are extensively used for biologic therapies. Biologics are complex molecules derived from living cells, used to treat various chronic and life-threatening conditions. These medications often require the combination of a lyophilized drug with a liquid solvent. Dual chamber cartridges ensure that these components remain separate until the point of administration, thereby preserving the medication’s integrity and therapeutic effectiveness.

Regulatory considerations are paramount when it comes to the use of dual chamber cartridges in pharmaceuticals. Compliance with FDA guidelines and other international regulatory standards is essential to ensure patient safety and treatment efficacy. These guidelines cover aspects such as the materials used in cartridge construction, sterility, and the stability of the stored medications. Pharmaceutical companies must rigorously test and validate their dual chamber cartridge systems to meet these regulatory requirements.

Overall, dual chamber cartridges play a crucial role in enhancing patient safety and treatment outcomes. By providing a reliable and efficient means of storing and administering complex medications, these cartridges help to ensure that patients receive the full therapeutic benefit of their prescribed treatments.

Applications in the Adhesives and Sealants Industry

Dual chamber vials have become an integral component in the adhesives and sealants industry, primarily due to their capacity for precise mixing of two-component materials. These specialized cartridges are engineered to store and dispense two separate components that must be mixed immediately prior to application. This is crucial for achieving the optimal performance of adhesives and sealants, especially in applications requiring high strength and reliability.

One of the significant advantages of dual chamber vials is their ability to ensure a consistent ratio between the two components, which is essential for the chemical reaction that forms the adhesive bond. By using these cartridges, manufacturers and end-users can avoid the common issues associated with manual mixing, such as uneven distribution and incomplete curing. This precision contributes to the overall durability and effectiveness of the adhesive or sealant.

Examples of successful implementations of dual chamber vials can be observed in various sectors. For instance, in the automotive industry, they are used for bonding and sealing parts that require high structural integrity, such as windshields and body panels. In the construction sector, dual chamber vials are utilized for sealing joints in buildings, particularly where a watertight seal is necessary. These applications benefit greatly from the precise mixing capabilities of dual chamber vials, ensuring that the adhesives and sealants perform as intended under demanding conditions.

Moreover, specific products like epoxy and polyurethane adhesives, which are widely used in both industrial and consumer markets, rely on dual chamber vials to deliver consistent and reliable results. These products often demand a rigorous mixing process to activate their full adhesive properties, making dual chamber vials an indispensable tool for achieving optimal performance.

In summary, dual chamber vials play a pivotal role in the adhesives and sealants industry by providing a reliable and efficient method for mixing two-component materials. Their precise mixing capabilities not only enhance the performance of adhesives and sealants but also contribute to the success of various applications across multiple industries.

Challenges and Considerations

When utilizing dual chamber cartridges, several challenges and considerations must be taken into account to ensure optimal performance and efficiency. One of the primary issues is the compatibility of materials. Dual chamber cartridges often involve the simultaneous dispensing of two different substances, which necessitates careful consideration of chemical compatibility. Incompatible materials can lead to contamination, compromised product integrity, and even hazardous reactions. Therefore, thorough testing and validation of the substances intended for use in dual chamber cartridges are critical steps in the planning phase.

The complexity of the filling process is another significant challenge. Unlike single chamber systems, dual chamber cartridges require precise filling techniques to ensure the correct ratio of materials in each chamber. Inaccurate filling can result in improper mixing at the point of application, negatively affecting the product’s performance. Advanced filling technologies and meticulous calibration are essential to achieving consistent and accurate filling. Specialized training for personnel involved in the filling process can also mitigate potential errors.

Cost implications are another consideration. Dual chamber cartridges and the associated filling and dispensing equipment can be more expensive than traditional single chamber systems. The need for specialized equipment, such as dual chamber dispensers, and the additional steps involved in the filling process contribute to higher upfront costs. However, these costs can be offset by the benefits of improved product performance, reduced waste, and enhanced user convenience. Careful cost-benefit analysis and strategic investment in quality equipment can help manage these financial challenges.

Furthermore, the necessity for specialized dispensing equipment cannot be overlooked. Dual chamber cartridges require dispensers that can handle the simultaneous release of two materials, ensuring proper mixing and application. Investing in high-quality, reliable dispensing equipment is crucial for maintaining product integrity and performance. Proper maintenance and regular calibration of dispensing equipment are also vital to avoid operational issues and ensure consistent results.

In conclusion, while dual chamber cartridges present certain challenges and considerations, these can be effectively managed through careful planning, thorough testing, and strategic investment in quality equipment and training. By addressing these challenges proactively, the benefits of dual chamber technology can be fully realized, offering enhanced product performance and user satisfaction.

Future Trends and Innovations

The landscape of dual chamber vials is poised for significant advancements, driven by the continuous integration of cutting-edge technologies and innovative solutions. One of the most promising developments on the horizon is the advent of smart cartridges equipped with built-in sensors. These intelligent systems are designed to monitor various parameters in real-time, including temperature, pressure, and flow rates, thereby enhancing the overall performance and reliability of dual chamber systems. By providing immediate feedback, these smart cartridges can prevent potential issues before they escalate, ensuring optimal functionality and extending the lifespan of the devices.

Moreover, digital tracking capabilities are set to revolutionize the way dual chamber vials are managed and utilized. With the integration of tracking technologies, such as RFID and IoT, users can maintain precise control over their inventory, monitor usage patterns, and streamline the supply chain processes. This level of digital oversight not only reduces the risk of errors but also facilitates predictive maintenance, where potential failures can be anticipated and addressed proactively.

The ongoing research and development efforts in this field are also focused on enhancing the efficiency and functionality of dual chamber systems. Researchers are exploring new materials and design innovations that can improve the compatibility and performance of the cartridges. For instance, advancements in biocompatible materials are making it possible to develop cartridges that are more suitable for delicate applications in the medical and pharmaceutical industries. Additionally, improvements in sealing technologies are aimed at minimizing the risk of cross-contamination and ensuring the purity of the substances contained within the chambers.

In summary, the future of dual chamber vials is bright, with numerous innovations set to transform the industry. From smart cartridges with built-in sensors to advanced digital tracking capabilities and ongoing R&D efforts, these advancements promise to elevate the efficiency, reliability, and functionality of dual chamber systems, paving the way for their broader application across various sectors.

Conclusion and Key Takeaways

Dual chamber cartridges have emerged as a transformative solution in various industries, offering significant advantages in terms of efficiency, precision, and versatility. Throughout this guide, we have explored the fundamental aspects of dual chamber cartridges, from their design and functionality to their diverse applications across sectors such as medical, industrial, and cosmetic.

One of the primary benefits of dual chamber cartridges is their ability to maintain the separation of two substances until the point of use. This feature ensures that the components remain stable and effective, thereby enhancing the quality and reliability of the final product. Additionally, dual chamber cartridges streamline the application process, minimizing waste and reducing the risk of contamination.

In the medical field, dual chamber cartridges are instrumental in the administration of complex medications, where precise dosages and the mixing of components at the time of delivery are crucial. In industrial applications, these cartridges facilitate the efficient combination of reactive substances, driving innovation and productivity. The cosmetic industry also leverages dual chamber technology to deliver products with enhanced performance and user experience.

As we look to the future, dual chamber cartridges are poised to play an even more significant role in advancing product development and application methods. Their adaptability and efficiency make them a valuable asset in addressing the evolving demands of various industries. By considering dual chamber cartridges, businesses can enhance their operational capabilities, ensure higher quality standards, and meet specific application requirements more effectively.

For those interested in exploring the potential of dual chamber cartridges further, we encourage you to consult with industry experts or delve into additional resources. Embracing this technology can lead to substantial improvements in product performance and operational efficiency, making it a worthwhile investment for forward-thinking organizations.

Reseñas

Aún no hay reseñas.